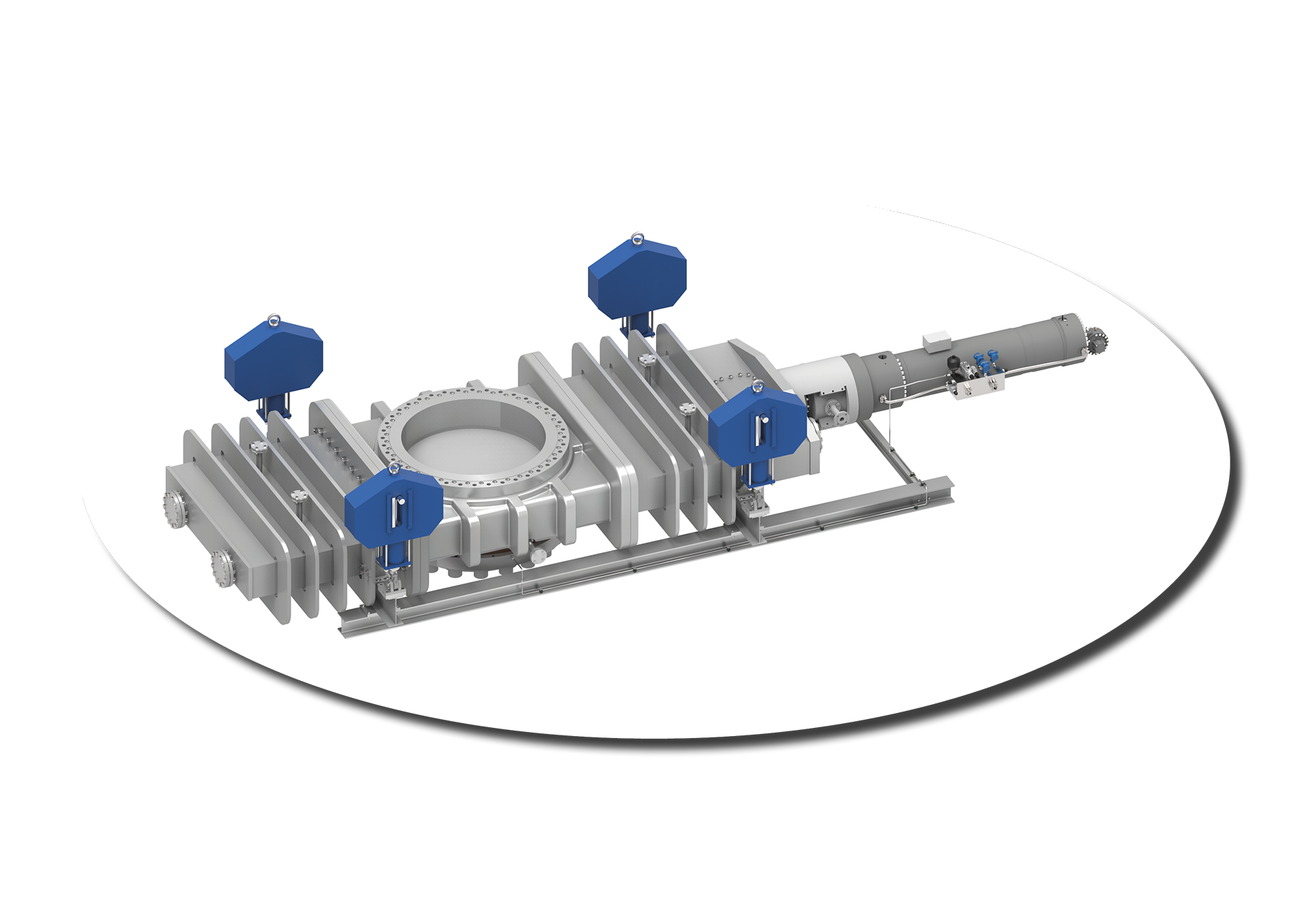

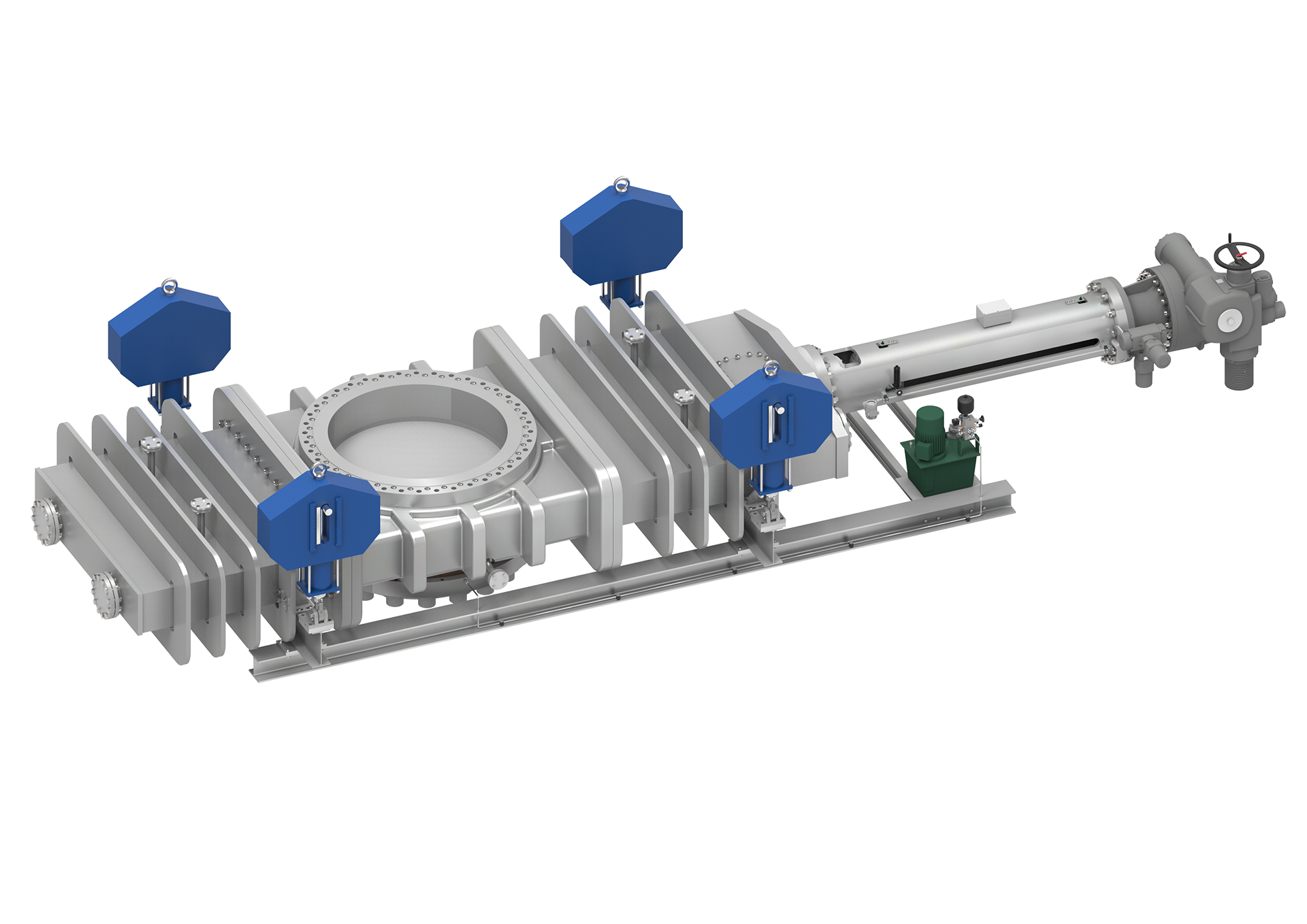

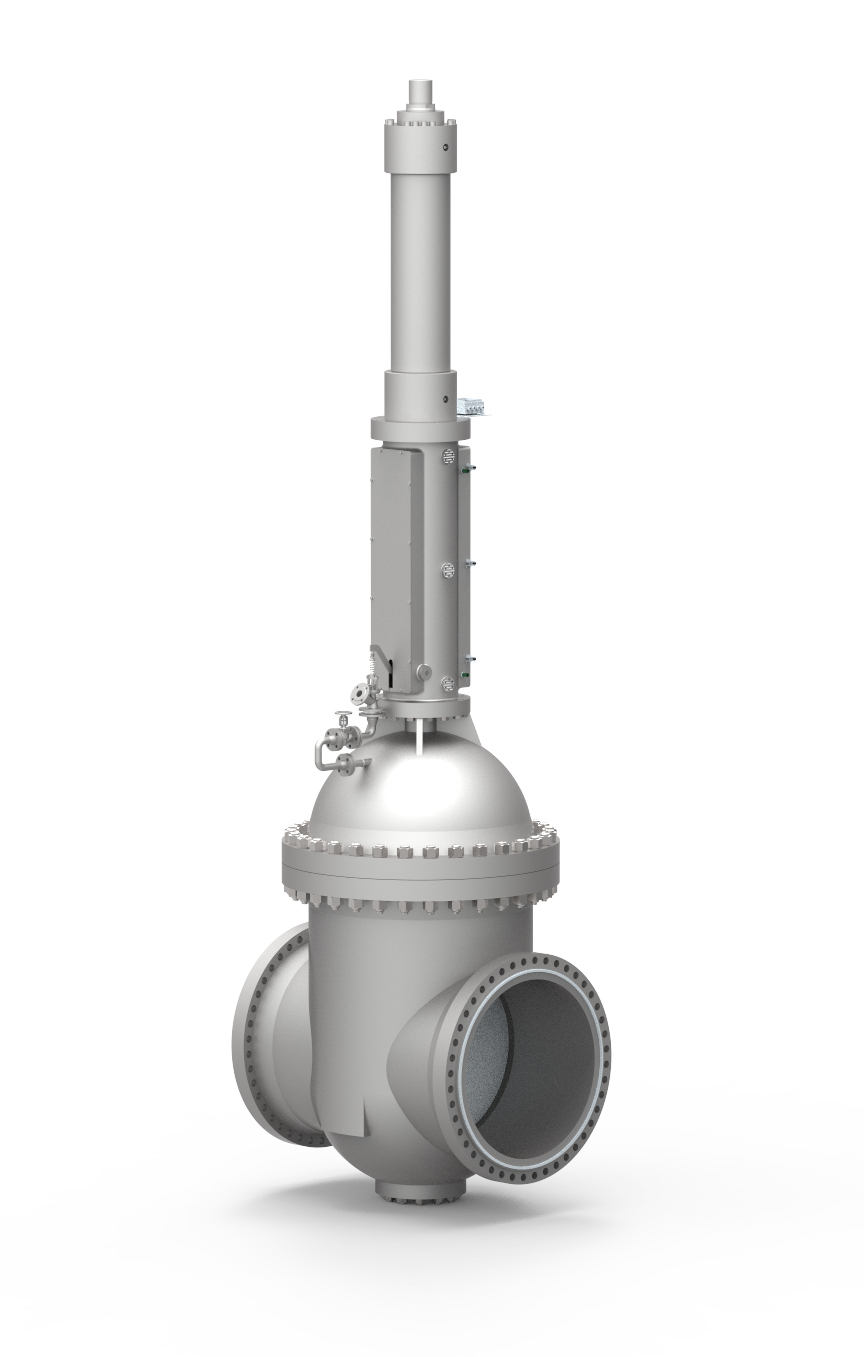

In the field of Delayed Coking process, VCL offers Automatic Bottom Unheading Valves tailored to your needs. Given the innovative design features, a patent application was introduced by VCL.

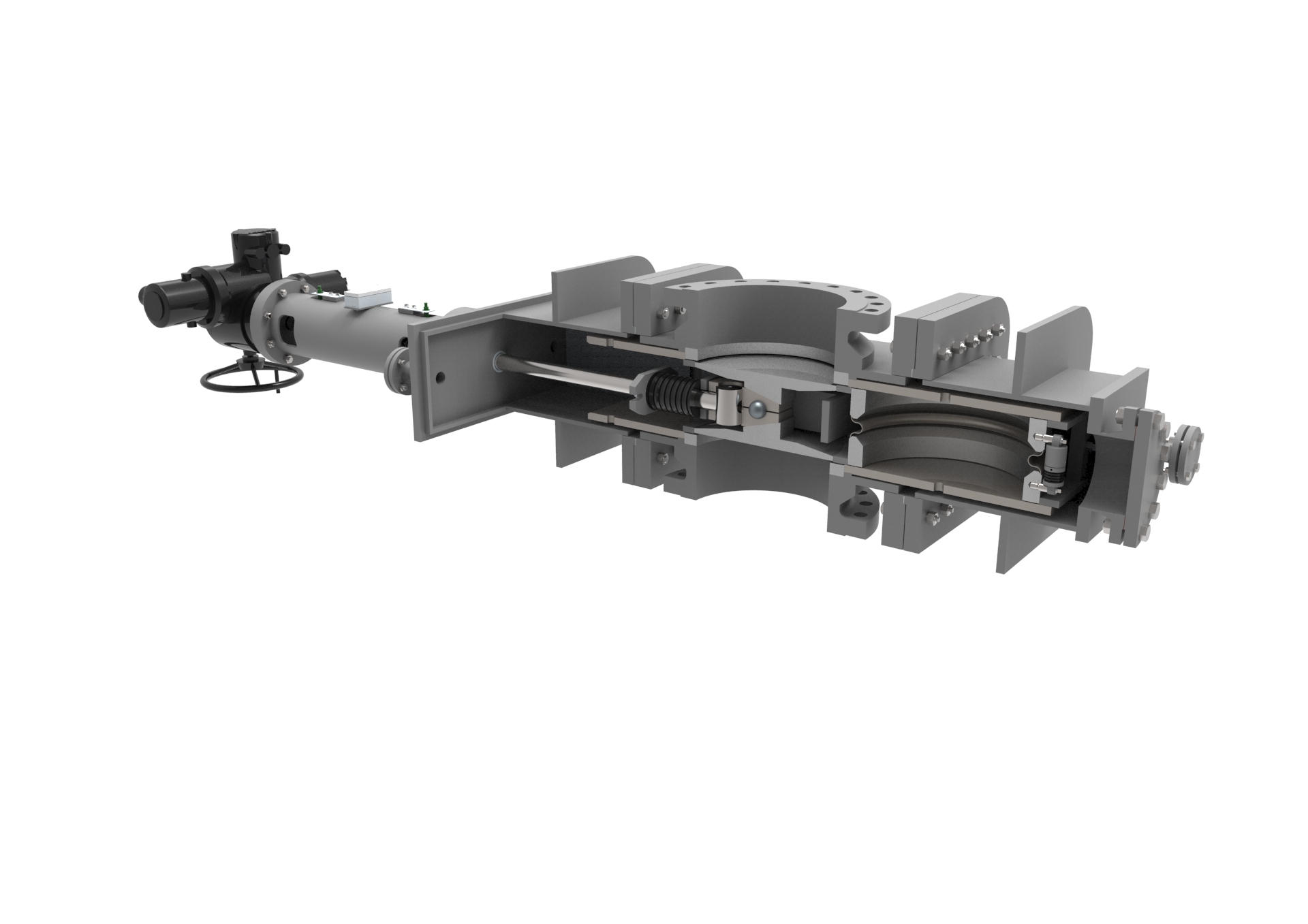

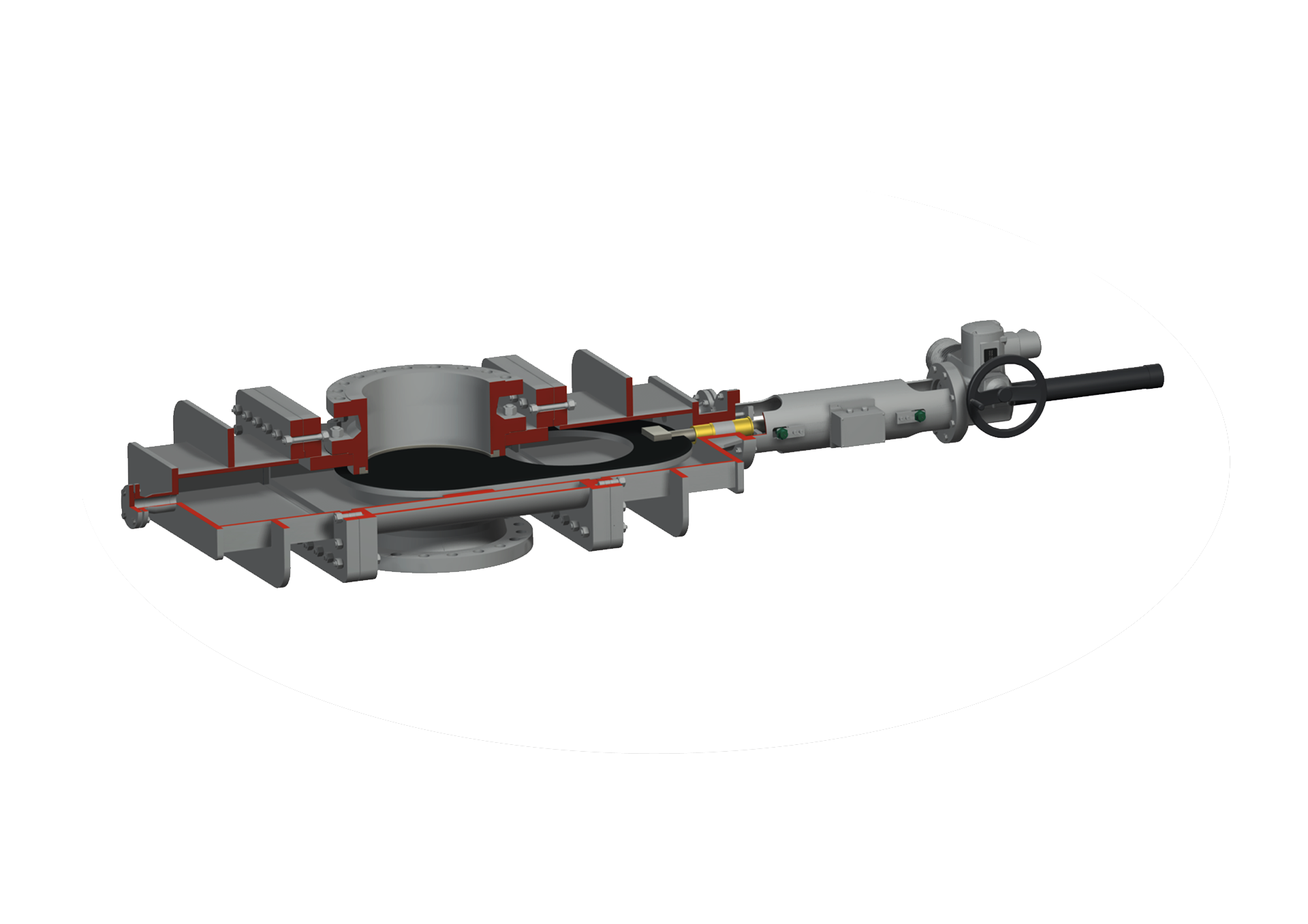

The unique VCL design combines the tightness of the classical Double Disc design and the low weight and small footprint of the classical single gate design.

The VCL Plate-Disc-Combination design with an external, active sealing force applied to the floating lower valve-body seat together with a circular shaped lower disc, guided by spherical caps, combines the advantages of the single-plate design with those of the double-disc design.

Subsequently, it offers an important innovation to the industry eliminating the disadvantages of competing classical concepts.

The new VCL sealing is a “floating” system, which is unaffected by any deformations caused by thermal stress or pressure issues.

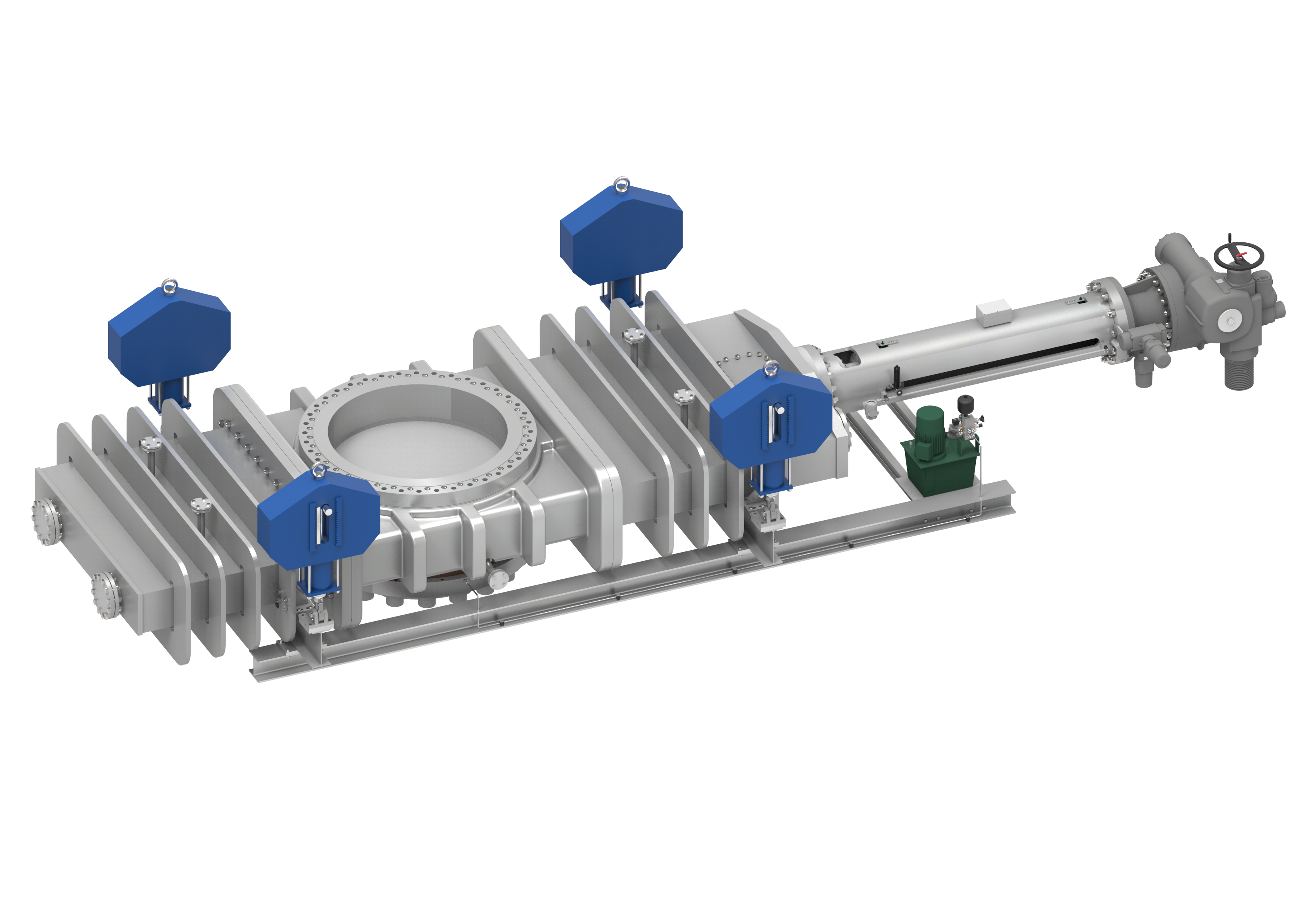

The valves are available with different actuator systems, with hydraulic power and control units as well as with steam purge systems.